FAIST Voices: meet Olifel

Under the FAIST, Olifel, a software provider company based in Felgueiras, is exploring how artificial intelligence can help footwear companies modernise their production processes under the FAIST project

The FAIST (Agile, Intelligent, Sustainable and Technological Factory) consortium brings together over 40 Portuguese partners across footwear and leather goods, technology providers and research centres. Running from June 2022 to June 2026, the programme channels about 50 million euros into projects that modernise the industry and sharpen its international competitiveness.

Olifel

The FAIST partner under the spotlight this week is Olifel, a Felgueiras-based software developer founded in 1988. The firm evolved from early hardware integrations to a portfolio of tailored digital solutions and now reports hundreds of active licences across manufacturers. Among the industries Olifel operates in, “the footwear sector remains the most challenging area”, Chief Executive Officer Rui Mendes shares.

According to Mendes, Olifel aims to democratise artificial intelligence (AI) for small and mid-sized firms, treating it as a core driver of competitiveness. With largely export-oriented clients, it applies AI to planning, marketing and end-to-end order follow-up (from samples to production). It is now expanding internationally as these solutions gain traction abroad.

Under the FAIST

As co-promoter of FAIST’s Work Package on digital platforms and tools, Olifel is piloting AI-assisted planning and scheduling for footwear and soles named Visualgest. The system weighs delivery dates, customer priorities, materials availability, machine capacity, moulds, colours and cycle times to generate multiple scenarios in minutes.

Mendes highlights that pilots are at different stages. At Armipex, expedition control using RFID (Radio Frequency Identification) is operational, while infrastructure and training are being rolled out with ISI and Carité. The final objective is to move from reactive to proactive control by shortening decision times, increasing plan adherence and giving operators clear targets on the shop floor.

Visualgest

More specifically, Visualgest (see figure below) is an integrated production-management module for the industry that turns factory data into proactive, AI-assisted schedules. It centralises workflows, allocates resources in real time and adjusts plans dynamically as orders, capacity, or materials change.

Managers gain predictive insights and fine-grained control, reducing interruptions, improving efficiency and aligning production with available resources for smarter, more reliable operations. The tool has 5 different modules.

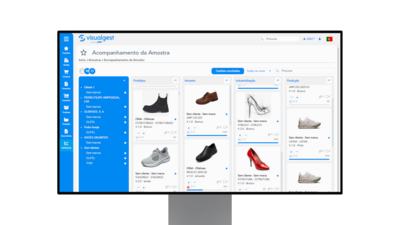

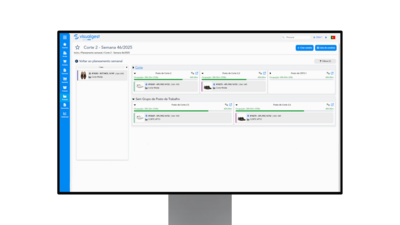

1) Sample Tracking. Module for managing the lifecycle of new samples from conception to production approval. A Kanban-style interface organises stages such as Prototype, Sample, Industrialisation and Production, giving sales and development teams transparent, real-time visibility of each sample in progress or already sold (see figure below).

2) Macro Planning. The primary control panel for factory-wide capacity. Provides a weekly (or custom period) view of workload by production line, helping to distribute tasks, spot utilisation peaks and balance capacity across lines (see figure below).

3) Workstation Planning. Drills the plan down to the operational level. Converts the macro plan into detailed orders per machine, workstation or workstation group, clarifying priorities, sequences and allocated times for each resource (see figure below).

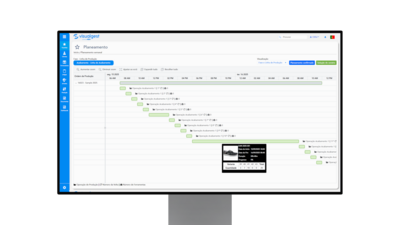

4) Gantt Planning. A time-based view of operations showing dependencies, durations and milestones along the schedule. Supports feasibility checks of the weekly plan and rapid reprogramming when deviations occur (see figure below).

5) Production Recording (Shop Floor). On-station interface (touchscreens/tablets) for real-time capture of production events. Records start, stop, quantities and incidents, feeding performance indicators and enabling immediate corrective actions in planning (see figure below).

FAIST Outcomes

Given the webtool, expected gains are concrete. Planning cycle time is set to fall from 8 hours to 1 hour, and schedule adherence should increase from 50% to 98.5%. Utilisation of critical resources, such as sole lines, is expected to rise from 60% to 84%. Work-in-process should drop from 10 to 2 units, while non-conformities decrease from 10 to 4 units.

Together, these shifts shorten planning and delivery, tighten the link between plan and execution, and improve costing accuracy through real-time data.

Image Credits: Olifel and FAIST