Portugal exports high-tech footwear to the world

Birkenstock, Burberry, Columbia, Hermès and Nike are some of the brands that use Portuguese high technology in their production. It’s a reality that will deepen over the next few years due to major investments being made as part of the FAIST mobilisation agenda

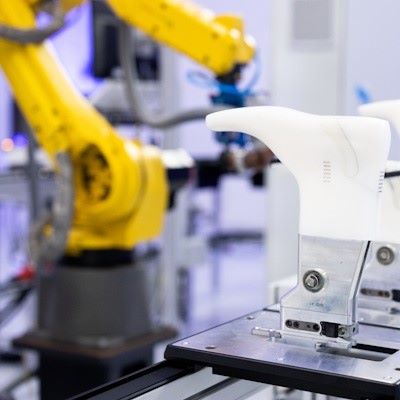

“We have created a whole ecosystem in Portugal that favours productive innovation and strengthens the link between universities and companies”, says Florbela Silva, coordinator of the FAIST project, which involves a PRR investment of around 50 million euros in automation and robotics.

“The Portuguese footwear industry is already one of the most advanced in the world”, but the ambition remains unchanged. “To remain at the forefront, the footwear sector must make a permanent contribution by investing in new, cutting-edge solutions to respond to a very demanding market dominated by Asian players”. In her view, this explains why Portugal was the only European country to increase production in the last decade.

The Portuguese company Mind, for example, already exports “its entire footwear product range, from conceptual design and product design solutions, product engineering to cutting solutions, automatic nesting or consumer estimation tools”, reveals Fernando Vasconcelos. The company’s portfolio includes a hundred clients such as Aokang, Berkemann, Birkenstock, Burberry, Columbia Footwear, Grendene or Hermès, to name a few of the best-known brands.

“There is a very positive general perception of Portuguese companies that develop technological products in the footwear sector”, stresses Fernando Vasconcelos, “with national companies being held up as examples in international sales for the quality and innovation of their solutions”. The work of APICCAPS and CTCP in the development of the Portuguese industry is also cited as an example and a model.

Fernando Ferro adds that “Portuguese companies are known for their combination of tradition and innovation, investing in advanced technologies and efficient production methods that improve the overall quality of their products”. According to the head of DCSI and Techlast, part of the Fernando Ferro & Irmão, S.A. universe, “the fact that Portugal is a leader in the field of sustainability, using environmentally friendly materials and practices, has greatly enhanced its brands”. The same goes for digitalisation and automation, which “have contributed to the competitiveness of the sector, allowing technological solutions to be customised”.

About FAIST

Created as a response to the needs of the footwear and leather goods sector, with a focus on digital technologies and the sustainability of processes and products, the FAIST Agenda - Agile, Intelligent, Sustainable and Technological Factory is changing the face of the sector, contributing “to greater efficiency and profitability, a quick response to the market, improved working conditions and product differentiation”, points out Florbela Silva.“By modernising and transforming the production processes of our national partners, we are creating solutions that not only increase efficiency and competitiveness, but also set new standards of excellence in the sector”, she recalls.

Source and Image Credits: apiccaps.pt