Register to continue reading for free

Gustavo Gonzalez-Quijano, from COTANCE: we are working on the regulatory areas that will shape future markets

We spoke to Gustavo Gonzalez-Quijano, who has been the Secretary General at COTANCE for more than 30 years. We discussed some of the critical issues around the European leather industry, including traceability standards and material metrics

Gustavo Gonzalez-Quijano has led COTANCE, the Brussels-based umbrella association for Europe’s leather industry, since 1987, coordinating national tanners’ associations from 10 countries that together account for more than 90% of the continent’s leather output.

A lawyer specialised in European law, Gonzalez-Quijano represents tanning-industry employers in the EU Social Sector Dialogue, chairs the CEN TC (European Committee for Standardisation Technical Committee) 289 on leather standardisation, co-founded the TCLF (Textile, Clothing, Leather and Footwear) Pact for Skills’ “TCLF Skills Alliance”, and serves as an expert to UNIDO’s (United Nations Industrial Development Organisation) Leather Unit, the FAO (Food and Agriculture Organisation) Sub-Group on Hides and Skins and the ILO (International Labour Organisation).

European Leather

European leather producers face a challenging market environment, with demand weakening across major regions and even the luxury segment beginning to soften. “The leather industry, and I mean here the entire value chain from livestock breeding until the manufacturers made with leather, needs thriving regulatory predictability and legal certainty in trade”, the Secretary General highlights.

However, Europe’s tanners remain resilient thanks to their size, structure, know-how and long-term vision. COTANCE is concentrating its policy work on dossiers likely to shape future markets, from the EU’s bio-economy strategy and circular-economy legislation to environmental footprint rules, textile labelling and Ecodesign rules.

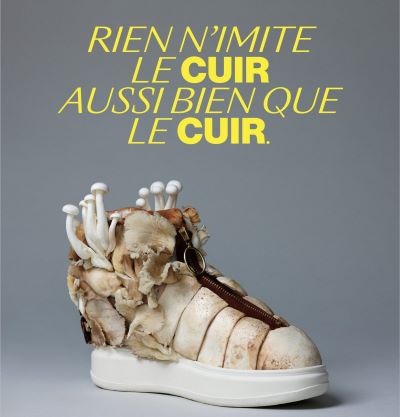

“Leather is a fabulous material, and European leather is the best in class”, Gonzalez-Quijano continues, “Leather ticks all the boxes that will make it the fashion material of predilection. It is not fossil-fuel-based but natural and renewable, bio-based and biodegradable at the end of life, it is durable and not fast-fashion, it is culture and brings biophilia”.

Traceability

Progress on end-to-end traceability is uneven. Shorter, predominantly European supply chains are advancing, but complex extra-EU routes remain challenging. A structural obstacle is that hides and skins are low-value by-products within the livestock chain, giving slaughterhouses limited incentive to invest in data exchange systems.

The Secretary General shares that “at least in Europe, slaughter animals are identified with their earmarks, but in many countries around the world, individual animal tracing is far from being a common feature”. COTANCE reports that European tanners can now routinely trace purchases back to the slaughterhouse and had forecast that farm-level traceability would not become standard before 2030.

After the adoption of the EU’s deforestation-free supply-chain regulation in 2022, the Leather Traceability Cluster brought together leading certification and audit bodies to define baseline requirements for traceability and verification. That work culminated in a protocol submitted for fast-track standardisation to CEN TC 289/Leather. Following public enquiry in September 2025, the resulting European Standard EN 18199 on leather traceability is expected in the first quarter of 2026.

According to Gonzalez-Quijano, “this will facilitate the setting up of traceability systems in the entire leather value chain and, with the foreseen mutual recognition, avoid duplication of certifications, audit fatigue and ultimately unproductive costs for the leather value chain”.

Materials

In comparing materials, the Secretary General is critical of durability metrics used in tools such as the PEFCR (Product Environment Footprint Category Rules) for Apparel & Footwear and the Higg Suite, arguing that fixed “wears” assumptions do not differentiate adequately between synthetics and natural materials.

“Their default values set is in ‘wears’, where every wear is a day. You will agree with me that 100 wears for quality leather footwear is ridiculous. It works well for fast-fashion plastic sneakers, where it is probably overestimated”, Gonzalez-Quijano emphasises. In contrast, he cites sectoral practice in the dry-cleaning industry’s Fair Claims Guide, where products made from synthetics are assigned shorter lifespans than leather or fur.

Brussels is still working through how to codify durability, repairability, end-of-life and verified impact within Ecodesign rules and environmental-footprint methodologies. “Yet what is obvious to anyone knowing and using leather, is that leather has unique and unmatched performance criteria in all these areas”, the Secretary General notes, though the technical work is ongoing.

Talent and Branding

Talent pipelines and sector branding are another priority. Rather than acting alone, COTANCE collaborates across the wider Textile, Clothing, Leather and Footwear ecosystem to gain critical mass. Joint Erasmus+ Blueprint projects are developing new curricula and training tools aimed at equipping the current and future workforce with relevant skills. Gonzalez-Quijano notes that “isolated, each of our sectors would not be able to achieve meaningful results”.

The confederation has also helped establish the TCLF Skills Alliance under the EU’s Pact for Skills, bringing together networks and stakeholders focused on competencies and training. “Together”, the Secretary General continues, “we are now promoting the development of Regional Skills Partnerships in TCLF regions. These should become privileged interlocutors for the development of skills initiatives and image campaigns”.

Image Credits: Art by Sofia Pádua